1. Umda

Le ncwadana ibandakanya ukusebenza kombane, i-pneumatic esebenzayo, i-hydraulic esebenzayo kunye ne-oyile-gas esebenza nge-flanged uqhagamshelwano lwe-flanged yamacandelo amathathu e-trunnion ibhola ye-valve kunye neevalvu zebhola ezidityanisiweyo ngokupheleleyo ezinobukhulu obubizwa ngokuba yi-NPS 8~36 & Class 300 ~ 2500.

2. Inkcazo yeMveliso

2.1 Iimfuno zobugcisa

2.1.1 Uyilo kunye nomgangatho wokwenziwa : API 6D, ASME B16.34

2.1.2 Ukuphela ukuya esiphelweni umgangatho woqhagamshelo: ASME B16.5

2.1.3 Umgangatho wobuso ngobuso: ASME B16.10

2.1.4 Umgangatho woxinzelelo lobushushu: ASME B16.34

2.1.5 Ukuhlolwa kunye novavanyo (kubandakanywa novavanyo lwe-hydraulic): API 6D

2.1.6 Uvavanyo lokumelana nomlilo: API 607

2.1.7 Ukulungiswa kokumelana nesulfure kunye nokuhlolwa kwezinto (ezisebenzayo kwinkonzo emuncu): NACE MR0175/ISO 15156

2.1.8 Uvavanyo lokukhutshwa kwempucuko (olusebenzayo kwinkonzo emuncu): ngokwe-BS EN ISO 15848-2 Udidi B.

2.2 Ubume bevalve yebhola

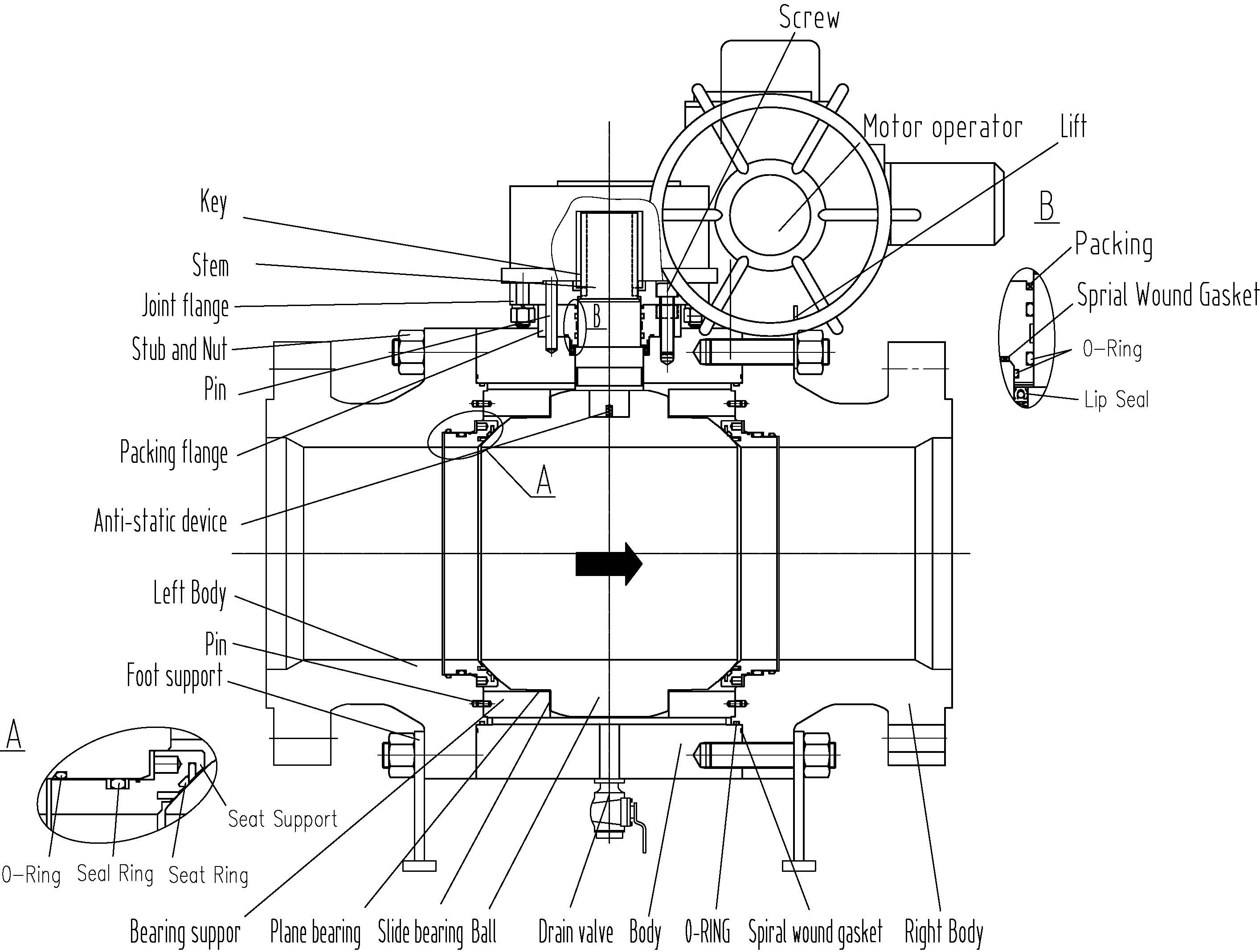

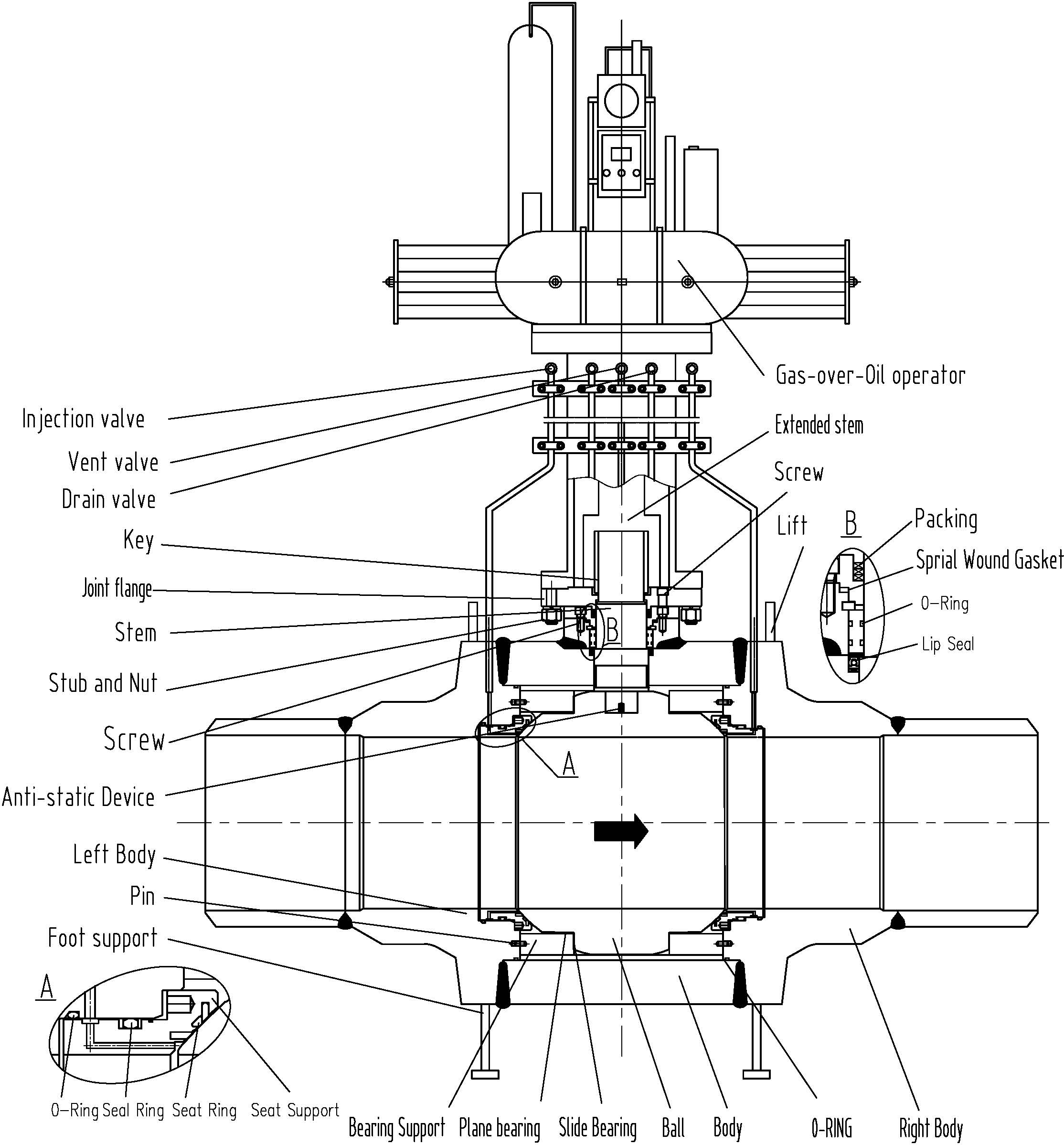

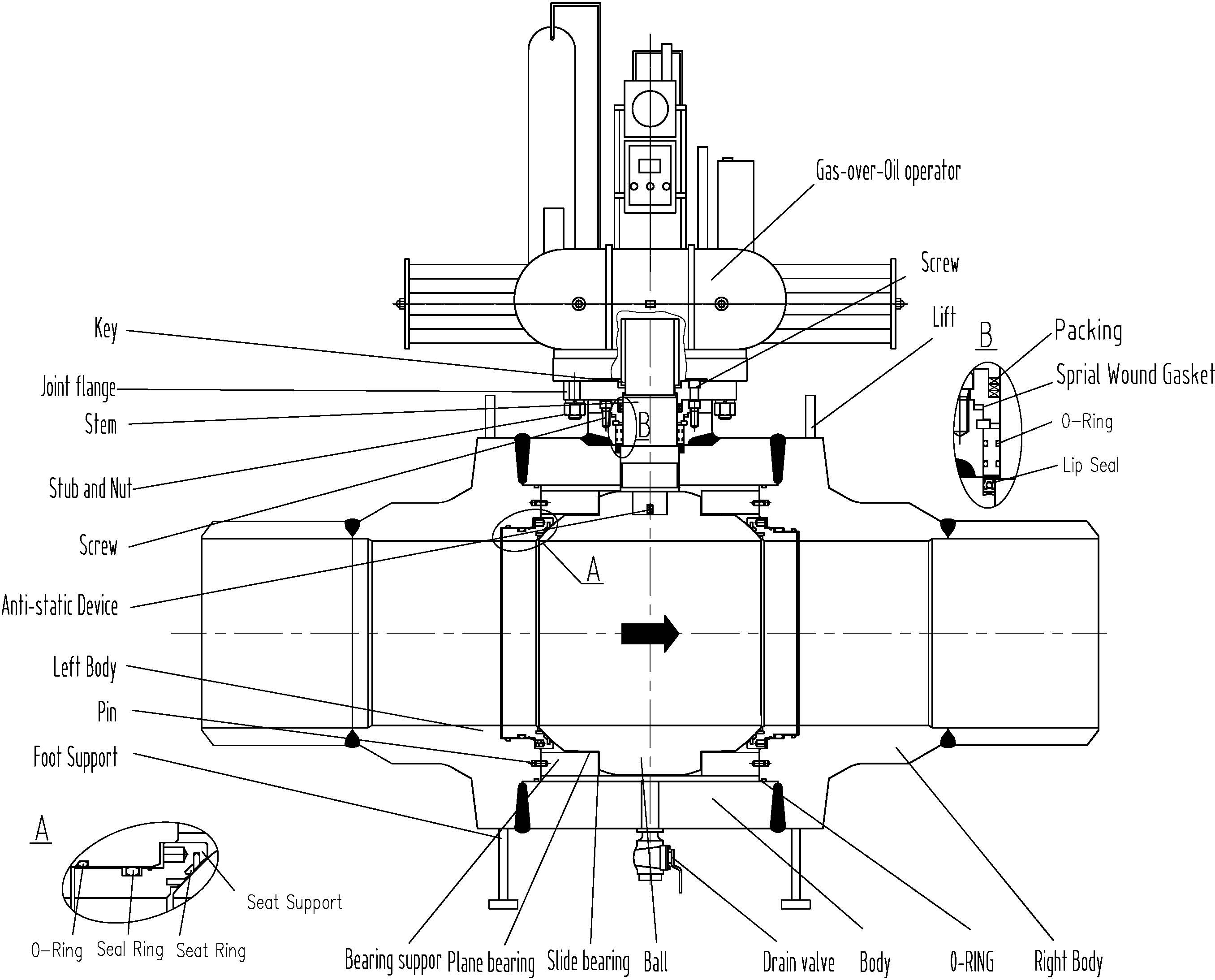

Umzobo1 Iziqwenga ezithathu ezenziwe ngeevalvu zebhola zetrunnion ezinombane osebenzayo

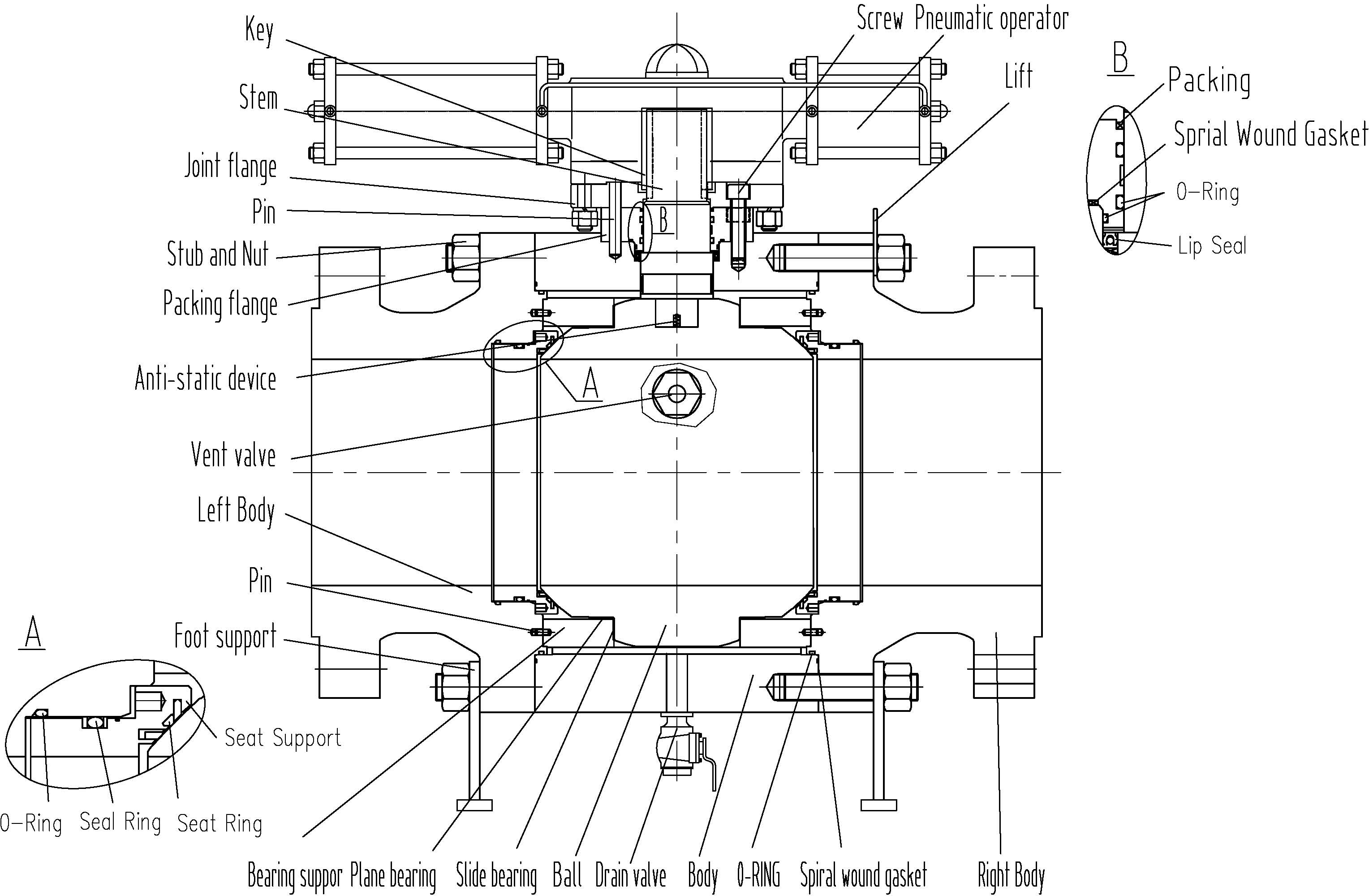

Umzobo2 Iziqwenga ezithathu ezenziwe ngeevalvu zebhola yetrunnion ene-pneumatic actuated

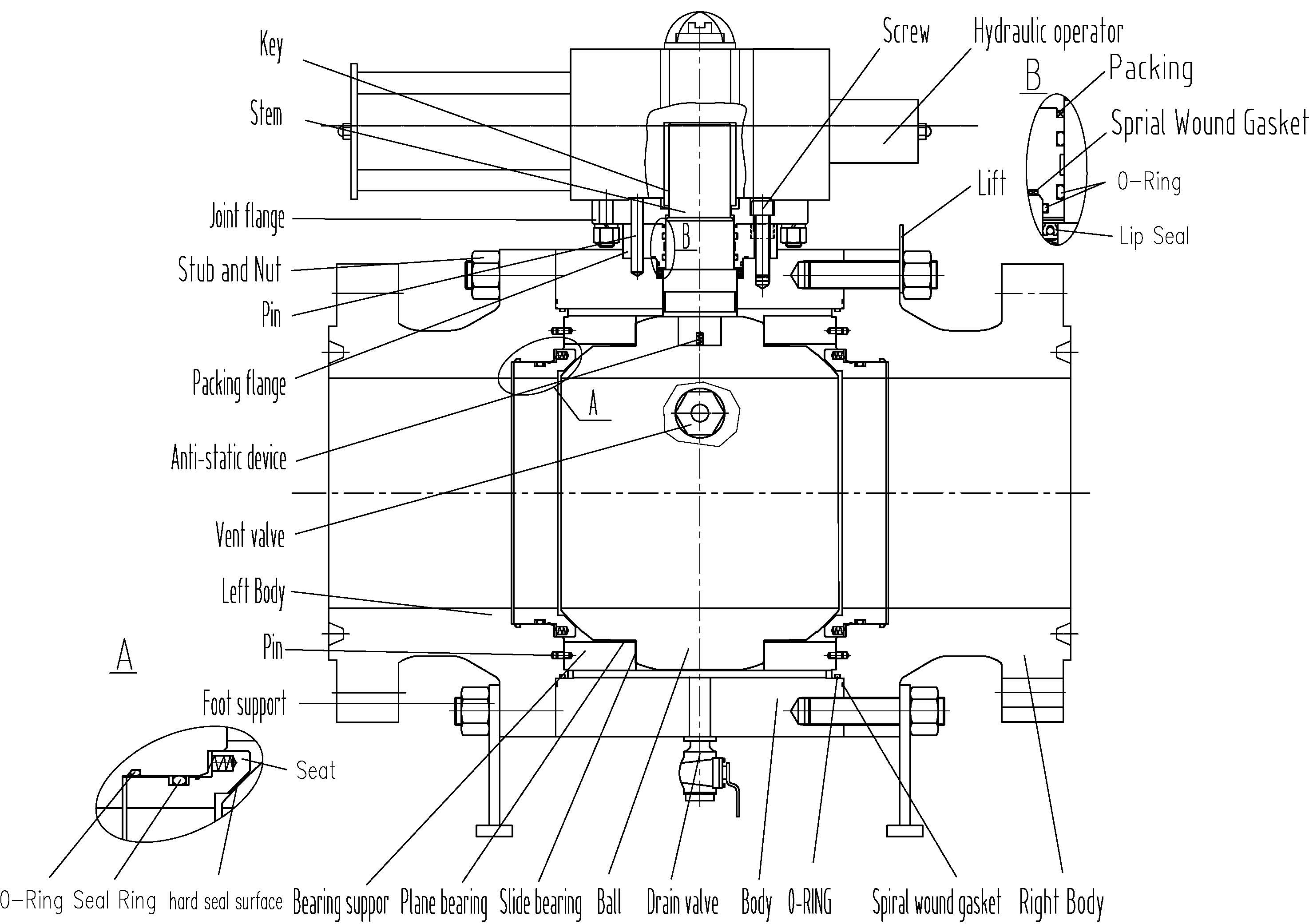

Umzobo3 Iziqwenga ezithathu ezenziwe ngeevalvu zebhola yetrunnion ene-hydraulic actuated

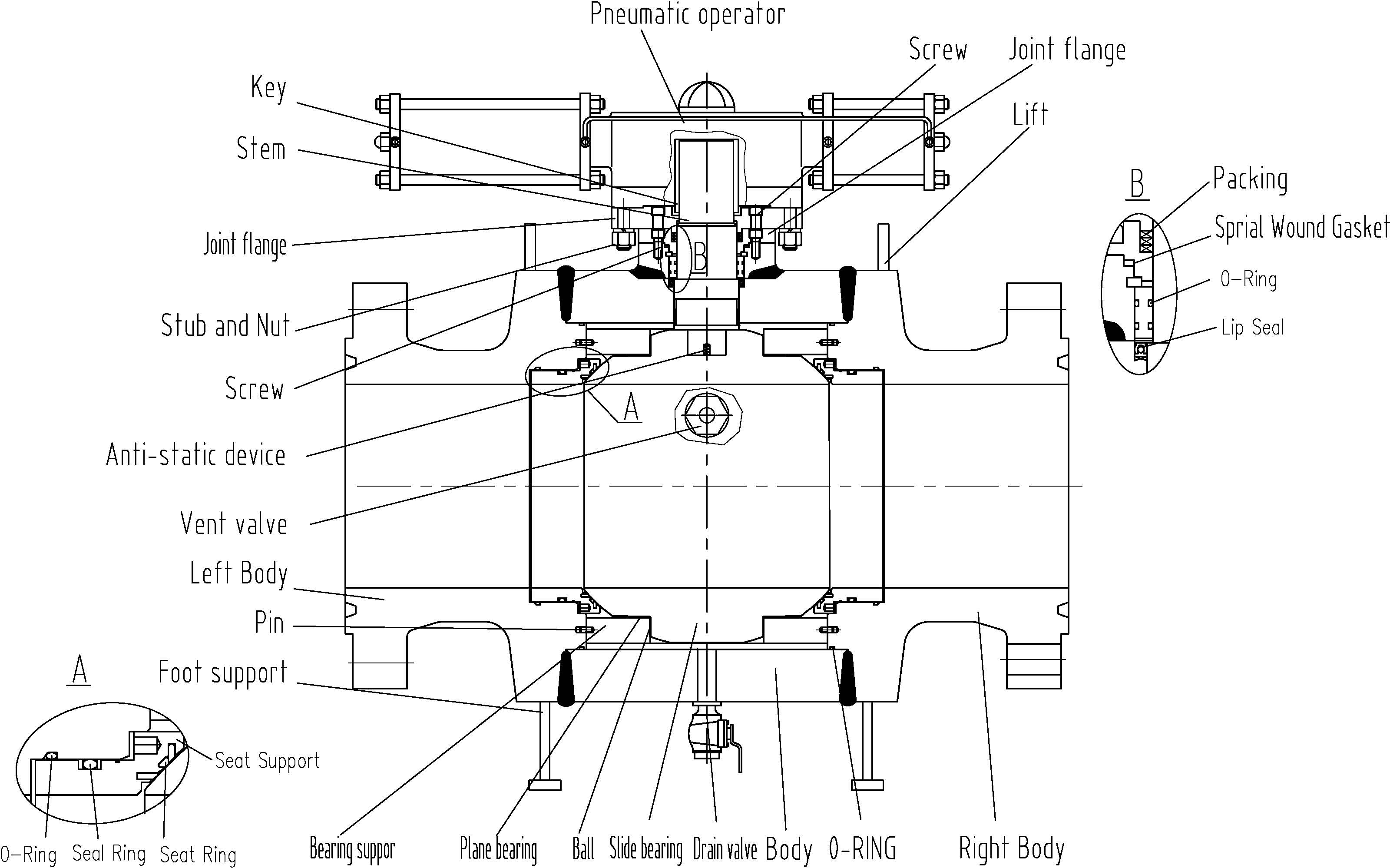

Umfanekiso4 Iivalvu zebhola ezidityaniswe ngokupheleleyo ezine-pneumatic actuated

Umzobo5 Ungcwatywe iivalvu zebhola ezidityaniswe ngokupheleleyo nge-oyile-gesi esebenzayo

Umzobo6 Iivalvu zebhola ezidityaniswe ngokupheleleyo ezinerhasi yeoli

3. Ufakelo

3.1 Ukulungiselela ukufakwa kwangaphambili

(1) Yomibini imibhobho yokuphela kwevalvu sele ilungile.Umphambili nasemva wombhobho kufuneka ube coaxial, umphezulu weflange wokutywina kufuneka uhambelane.

(2) Imibhobho ecocekileyo, ubumdaka obunamafutha, i-welding slag, nazo zonke ezinye izinto ezingcolileyo zifanele zisuswe.

(3) Qwalasela ukuphawulwa kwevalve yebhola ukuchonga iivalvu zebhola ezikwimo elungileyo.Ivalve iya kuvulwa ngokupheleleyo kwaye ivalwe ngokupheleleyo ukuqinisekisa ukuba isebenza kakuhle.

(4) Susa izincedisi ezikhuselayo ekudibaneni kweziphelo zombini zevalve.

(5) Jonga indawo evulekileyo yevalvu kwaye uyicoce kakuhle.Izinto zangaphandle phakathi kwesitulo sevalve/iringi yesihlalo kunye nebhola, nokuba yigranule kuphela enokonakalisa ubuso bokutywina kwesitulo sevalve.

(6)Phambi kofakelo, khangela ngononophelo i-nameplate ukuqinisekisa uhlobo lwesivalo, ubungakanani, izinto zokuhlala kunye nomgangatho wobushushu boxinzelelo olufanelekileyo kwimeko yombhobho.

(7)Phambi kofakelo, khangela zonke iibholiti kunye namantongomane kuqhagamshelo lwevalve ukuqinisekisa ukuba iqinisiwe.

(8)Ukuhamba ngononophelo kwezothutho, ukujula okanye ukuwisa akuvumelekanga.

3.2 Ukufakela

(1) Ivalve efakwe kumbhobho.Ngeemfuno zokuhamba kwemidiya yevalvu, qinisekisa umlambo onyukayo kunye nosezantsi ngokuhambelana necala levalvu ekufuneka ifakwe.

(2) Phakathi kweflange yevalve kunye neflange yombhobho kufuneka kufakwe iigaskets ngokweemfuno zoyilo lombhobho.

(3) Iibholithi zeflange kufuneka zilingane, zilandelelane, ziqiniswe ngokulinganayo

(4) Izivalo ezidityanisiweyo ezidityanisiweyo ziya kuthi ubuncinane zifezekise ezi mfuno zilandelayo xa zidityanisiwe ukuze zifakwe kwinkqubo yemibhobho kwisiza:

a.Ukuwelda kufuneka kuqhutywe ngumshiseli onesatifikethi sesiqinisekiso se-welder esivunywe nguGunyaziwe weSibhobho soBume kunye noxinzelelo;okanye umtyibilikisi ofumene isiqinisekiso sesiqinisekiso somtshisi esichazwe kwi-ASME Vol.Ⅸ.

b.Iiparameters zenkqubo ye-welding kufuneka zikhethwe njengoko zichazwe kwincwadana yokuqinisekisa umgangatho wezinto eziphathekayo

c.Ukwakhiwa kweekhemikhali, ukusebenza koomatshini kunye nokumelana nokubola kwentsimbi yokuzalisa i-welding seam kufuneka ihambelane nesiseko sesinyithi.

(5) Xa uphakamisa ngelugi okanye intamo yevalve kunye netyathanga lokusawula eligcina kwivili lesandla, ibhokisi yegiya okanye ezinye ii-actuators azivumelekanga.

(6) Umzimba wevalve yebhola edityanisiweyo usuka kwi-butt end weld 3 "nakweyiphi na indawo engaphandle kweqondo lobushushu aliyi kuba ngaphezu kwama-200 ℃. Phambi kwe-welding, amanyathelo kufuneka athathwe ukuthintela ukungcola okufana ne-welding slag kwi-welding Inkqubo yokuwela kumjelo womzimba okanye isihlalo esitywiniweyo Umbhobho othumele indawo ebuthathaka yokuhlwa kufuneka uthathelwe umlinganiselo wobulukhuni be weld Ukuqina komthungo wokuwelda kunye nesiseko semathiriyeli ayikho ngaphezulu kwe-HRC22.

(7)Xa ufaka iivalvu kunye ne-actuator, i-axis ye actuator worm kufuneka ijonge kwi-axis yombhobho.

3.3 Ukuhlolwa emva kofakelo

(1) Ukuvula nokuvala amaxesha ama-3–5 eevalvu zebhola kunye ne-actuators makungavalwa kwaye kuqinisekisa ukuba iivalvu zinokusebenza ngokuqhelekileyo.

(2) Umdibaniso wobuso beflange phakathi kombhobho kunye nevalve yebhola kufuneka uhlolwe ukusebenza kokutywina ngokweemfuno zoyilo lombhobho.

(3)Emva kofakelo, uvavanyo loxinzelelo lwenkqubo okanye umbhobho, ivalve kufuneka ibe kwindawo evuleke ngokupheleleyo.

4 .Ukusebenza, ukugcinwa kunye nokugcinwa

4.1 Ivalve yebhola yi-90 °uhlobo lokuvula nokuvala, ivalve yebhola isetyenziselwa ukutshintsha kuphela kwaye ayisetyenziselwa ukulungiswa!Akuvumelekile ukuba i-valve isetyenziswe kwiqondo lokushisa elingentla kunye nomda woxinzelelo kunye noxinzelelo oluguqukayo rhoqo, ubushushu kunye nemeko yokusebenza yokusetyenziswa.Iqondo loxinzelelo lobushushu liya kuhambelana nomgangatho we-ASME B16.34.Iibholithi kufuneka ziqiniswe kwakhona kwimeko yokuvuza kwiqondo lokushisa eliphezulu.Musa ukuvumela ukuchaphazela ukulayisha kunye nesenzeko soxinzelelo oluphezulu aluvumeli ukubonakala kwiqondo lokushisa eliphantsi.Abavelisi abanaxanduva ukuba kwenzeka ingozi ngenxa yokuphulwa kwemithetho.

4.2 Umsebenzisi kufuneka azalise ioli yokuthambisa (igrisi) rhoqo ukuba kukho naziphi na iivalvu zegrisi ezizezohlobo lwelube.Ixesha kufuneka limiselwe ngumsebenzisi ngokwexesha lokuvula kwevalve, ngokuqhelekileyo kanye emva kweenyanga ezintathu;ukuba kukho naziphi na iivalvu zegrisi ezizezohlobo lwetywina, igrisi yokutywina okanye ukupakishwa okuthambileyo kufuneka kuzaliswe kwangexesha ukuba abasebenzisi bafumene ukuvuza, kwaye iqinisekisa ukuba akukho kuvuza.Umsebenzisi uhlala egcina izixhobo zikwimeko entle!Ukuba kukho iingxaki ezisemgangathweni ngexesha lewaranti (ngokwesivumelwano), umenzi kufuneka aye kwindawo yesehlakalo ngokukhawuleza kwaye asombulule ingxaki.Ukuba ngaphezu kwexesha lewaranti (ngokwesivumelwano), xa umsebenzisi efuna ukuba sisombulule ingxaki, siya kwindawo yesehlakalo ngokukhawuleza kwaye sisombulule ingxaki.

4.3 Ukujikeleziswa ngasekunene kweevalvu zokusebenza ngesandla kuya kuvalwa kwaye ukujikeleziswa okuchasene newotshi kweevalvu zokusebenza ngesandla kuya kuvuleka.Xa ezinye iindlela, iqhosha lebhokisi yokulawula kunye nemiyalelo kufuneka ihambelane nokutshintsha kweevalvu.Kwaye uphephe ukusebenza okungalunganga kuya kuphepha ukwenzeka.Abavelisi abanaluxanduva ngenxa yeempazamo zokusebenza.

4.4 Iivalvu kufuneka zigcinwe rhoqo emva kokusetyenziswa kweevalvu.Ubuso obutywiniweyo kunye nokulimala kufuneka kuhlolwe rhoqo, njengokuba ukupakisha kuyaguga okanye ukusilela;ukuba kwenzeka umhlwa.Ukuba le meko ingentla iyenzeka, lixesha lokulungiswa okanye ukubuyisela.

4.5 Ukuba i-medium ngamanzi okanye i-oyile, kucetyiswa ukuba iivalve kufuneka zihlolwe kwaye zigcinwe rhoqo kwiinyanga ezintathu.Kwaye ukuba i-medium is corrosive, kucetyiswa ukuba zonke iivalve okanye inxalenye yevalve kufuneka ihlolwe kwaye igcinwe inyanga nenyanga.

4.6 Ivalve yebhola ngokuqhelekileyo ayinayo i-thermal insulation structure.Xa iqondo lokushisa eliphakathi liphezulu okanye liphantsi, umphezulu wevalve awuvumelekanga ukuba uthintele ukuthintela ukutshisa okanye i-frostbite.

4.7 Umphezulu weevalvu kunye nesiqu kunye namanye amalungu agubungela ngokulula uthuli, i-oyile kunye nentsholongwane ephakathi.Kwaye ivalve kufuneka ibe yi-abrasion kunye ne-corrosion ngokulula;nokuba ibangelwa bubushushu bokukhuhlana obudala umngcipheko werhasi eqhumayo.Ngoko ivalve kufuneka icoceke rhoqo ukuze kuqinisekiswe ukusebenza kakuhle.

4.8 Xa kulungiswa ivalve kunye nokugcinwa kwayo, kufuneka kusetyenziswe ubungakanani bokuqala kunye ne-o-rings ye-material, iigaskets, iibholithi kunye namandongomane.I-O-rings kunye ne-gaskets ye-valve ingasetyenziselwa ukulungiswa kunye nokugcinwa kweendawo ezisecaleni kwi-oda lokuthenga.

4.9 Akuvumelekanga ukususa ipleyiti yokudibanisa ukuze ithathe indawo ye-bolts, nuts kunye ne-o-rings xa i-valve ikwimeko yoxinzelelo.Emva kwezikrufu, iibholiti, amandongomane okanye i-o-rings, iivalve zingaphinda zisetyenziswe emva kovavanyo lokutywinwa.

4.10 Ngokubanzi, iindawo zangaphakathi zeevalve kufuneka zikhethe ukulungiswa kunye nokutshintshwa, kungcono ukusebenzisa iinxalenye zabenzi bokutshintshwa.

4.11 Iivalve kufuneka zidityaniswe kwaye zilungiswe emva kokuba iivalve zilungiswe.Kwaye kufuneka zivavanywe emva kokuba zidityanisiwe.

4.12 Akukhuthazwa ukuba umsebenzisi aqhubeke elungisa ivalve yoxinzelelo.Ukuba iindawo zokugcina uxinzelelo zisetyenziswe ixesha elide, kwaye ingozi enokwenzeka iya kwenzeka, kwaye ichaphazela ukhuseleko lomsebenzisi.Abasebenzisi kufuneka babuyisele ivalve entsha kwangethuba.

4.13 Indawo yokuwelda yeevalvu ze-welding kumbhobho akuvumelekanga ukulungiswa.

4.14 Iivalvu ezikumbhobho azivumelekanga ukuba zicofe;yeyokuhamba nje, nanjengayo nayiphi na into enzima phezu kwayo.

4.15 Iziphelo kufuneka zigqunywe ngesikhuselo kwigumbi elomileyo nelingena umoya, ukuqinisekisa ubunyulu bomngxuma wesivalo.

4.16 Iivalvu ezinkulu kufuneka zixhaswe phezulu kwaye azikwazi ukunxulumana nomhlaba xa zigcina ngaphandle Kwakhona, ukungenwa kwamanzi okungqina ukufuma kufuneka kuqatshelwe.

4.17 Xa i-valve yokugcina ixesha elide iphinda isetyenziswe kwakhona, ukupakishwa kufuneka kuhlolwe ukuba akuvumelekile kwaye kuzalise ioli ye-lubricant kwiindawo ezijikelezayo.

4.18 Iimeko zokusebenza kwesivalo kufuneka zihlale zicocekile, kuba zinako ukwandisa ubomi bayo benkonzo.

4.19 Ivalve yokugcina ixesha elide kufuneka ihlolwe rhoqo kwaye isuse ukungcola.Umphezulu wokutywina kufuneka ubeke ingqalelo ukuba ucoceke ukuthintela umonakalo.

4.20 Ipakethe yokuqala iyagcinwa;Umphezulu weevalvu, i-stem shaft kunye ne-flange indawo yokutywina ye-flange kufuneka inikele ingqalelo ukukhusela.

4.21 Umngxunya weevalvu awuvumelekanga ukuba ukhuphe xa ukuvulwa kunye nokuvala kungafiki kwindawo echongiweyo.

5. Iingxaki ezinokwenzeka, izizathu kunye namanyathelo okulungisa (jonga uxwebhu loku-1)

IFomu 1 Iingxaki ezinokwenzeka, izizathu kunye namanyathelo okulungisa

| Inkcazo yengxaki | Unobangela onokwenzeka | Amanyathelo okulungisa |

| Ukuvuza phakathi kwendawo yokutywina | 1. Umphezulu omdaka wokutywina2.Umphezulu wokutywina wonakele | 1. Susa ukungcola2.Yilungise kwakhona okanye uyitshintshe |

| Ukuvuza ekupakishweni kwesikhondo | 1. Ukupakisha ukucinezela amandla akwanele2.Ukupakishwa okonakele ngenxa yenkonzo yexesha elide I-3.O-ring yebhokisi yokuhlohla ayiphumelelanga | 1. Qinisa izikrufu ngokulinganayo ukudibanisa ukupakisha2.Indawo yokupakisha

|

| Ukuvuza ekudibaneni phakathi komzimba wevalvu kunye nomzimba wasekhohlo-wasekunene | 1.Iibholiti zoqhagamshelo ziqinisa ukungalingani2.Ubuso beflange eyonakeleyo 3. Iigaskets ezonakalisiweyo | 1. Iqiniswe ngokulinganayo2.Yilungise 3. Faka iigaskets endaweni yazo |

| Ukuvuza kwevalve yegrisi | Ubutyobo bungaphakathi kweevalvu zegrisi | Coca ngolwelo oluncinci lokucoca |

| Yonakele ivalve yegrisi | Faka kwaye ubuyisele igrisi encedisayo emva kokuba umbhobho unciphise uxinzelelo | |

| Ukuvuza kwevalve yokukhupha amanzi | Konakala ukutywinwa kwevalve yokukhupha amanzi | Ukutywinwa kweevalve zombhobho kufuneka kuhlolwe kwaye kucocwe okanye kutshintshelwe ngokuthe ngqo.Ukuba yonakele kakhulu, iivalve zombhobho kufuneka zitshintshwe ngokuthe ngqo. |

| Ibhokisi yegiya/i-activator | Ukusilela kwebhokisi yegiya/ye actuator | Lungisa, lungisa okanye utshintshe ibhokisi yegiya kunye ne-actuator ngokwebhokisi yegiya kunye neenkcukacha ze-actuator |

| Ukuqhuba akubhetyebhetye okanye ibhola ayivuli okanye ivale. | 1. Ibhokisi yokuhlohla kunye nesixhobo soqhagamshelwano si-skewed2.Isiqu kunye namalungu aso awonakele okanye amdaka. 3. Amaxesha amaninzi ukuvula nokuvala kunye nokungcola kumphezulu webhola | 1. Lungisa ukupakisha, ibhokisi yokupakisha okanye isixhobo sokudibanisa.2.Vula, lungisa kwaye ususe ugutyulo 4.Vula ,coca kwaye ususe ilindle |

Qaphela: Umntu wenkonzo kufuneka abe nolwazi olufanelekileyo kunye namava ngeevalvu

Ixesha lokuposa: May-19-2022