1. Umda

Ubalulo lubandakanya i-NPS ye-NPS 10~NPS48 eQhelekileyo, udidi oluQhelekileyo loxinzelelo (150LB~300LB) olune-flanged triple eccentric metal seal butterfly valves.

2. Inkcazo yeMveliso

2.1 Iimfuno zobugcisa

2.1.1 Uyilo kunye nomgangatho woMveliso: API 609

2.1.2 Ukuphela ukuya esiphelweni umgangatho woqhagamshelo:ASME B16.5

2.1.3 Umgangatho wobuso ngobuso: API609

2.1.4 Umgangatho webakala loxinzelelo lobushushu:ASME B16.34

2.1.5 Ukuhlolwa kunye novavanyo (kubandakanya uvavanyo lwe-hydraulic): API 598

2.2 Imveliso ngokubanzi

Ivalve yebhabhathane ene-eccentric eccentric etywinwa kabini yentsimbi yenye yeemveliso eziphambili ze-BVMC, kwaye isetyenziswa ngokubanzi kwisinyithi, ishishini lokukhanya, amandla ombane, i-petrochemical, ijelo legesi kunye namanye amacandelo.

3. Iimpawu kunye nesicelo

Isakhiwo si-eccentric kathathu kunye nentsimbi ehleliyo.Inokusebenza kakuhle kokutywinwa phantsi kwemeko yokushisa kwegumbi kunye / okanye ukushisa okuphezulu.Umthamo omncinci, ubunzima obulula, ukuvula kunye nokuvala ngokuguquguqukayo kunye nobomi obude bokusebenza ziinzuzo zayo ezicacileyo xa kuthelekiswa neevalvu zesango okanye iivalvu zeglowubhu.Isetyenziswa ngokubanzi kwi-metallurgy, imboni yokukhanya, amandla ombane, i-petrochemical, i-channel yegesi yamalahle kunye nezinye iindawo, ukusetyenziswa kokhuseleko oluthembekileyo, i-valve lolona khetho lufanelekileyo lwamashishini anamhlanje.

4.Isakhiwo

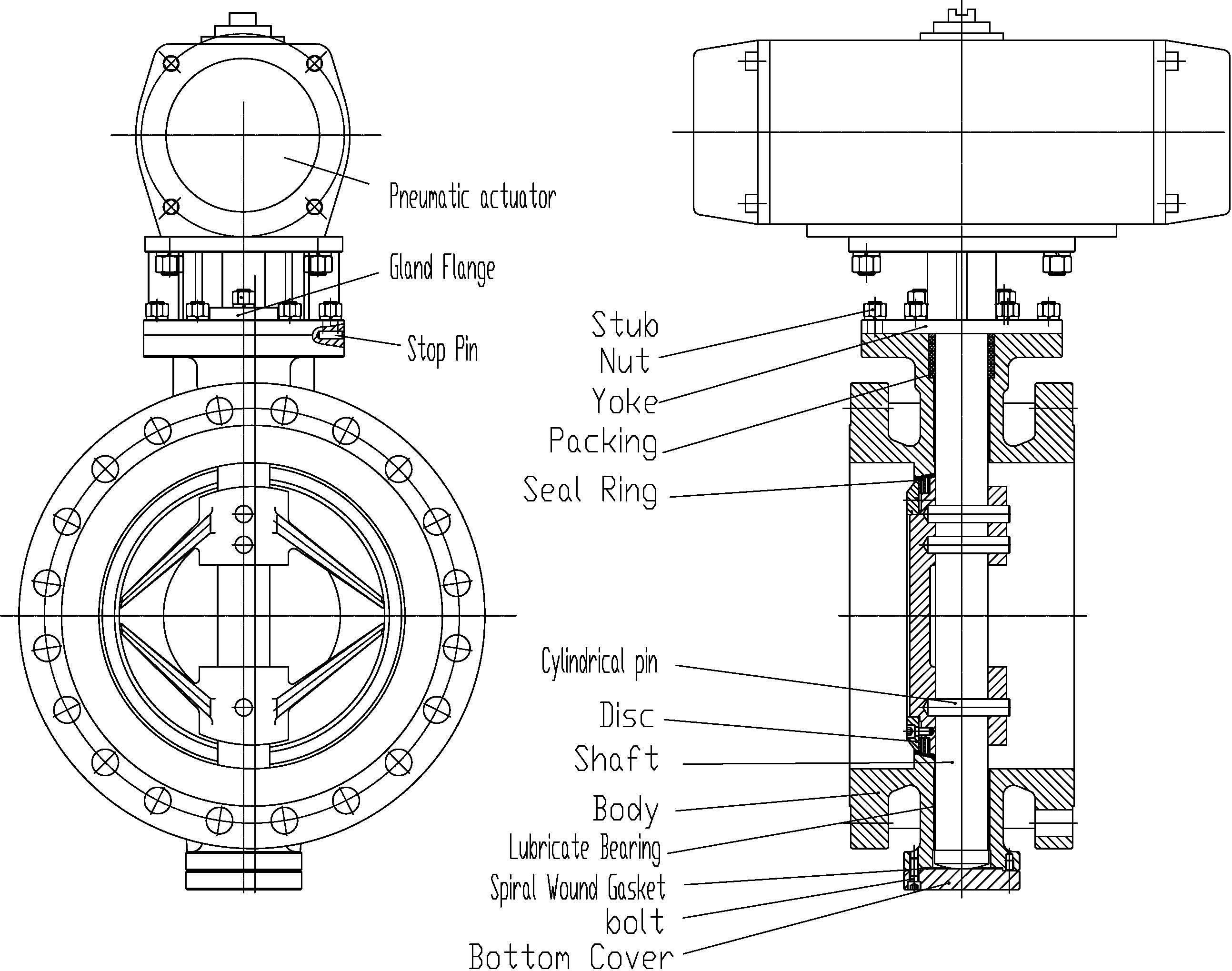

4.1 Ivalve yebhabhathane yentsimbi etywiniweyo kathathu njengoko kubonisiwe kuMzobo woku-1

Umzobo 1 Ivalve yebhabhathane yentsimbi etywiniweyo kathathu

5. Umgaqo wokutywina:

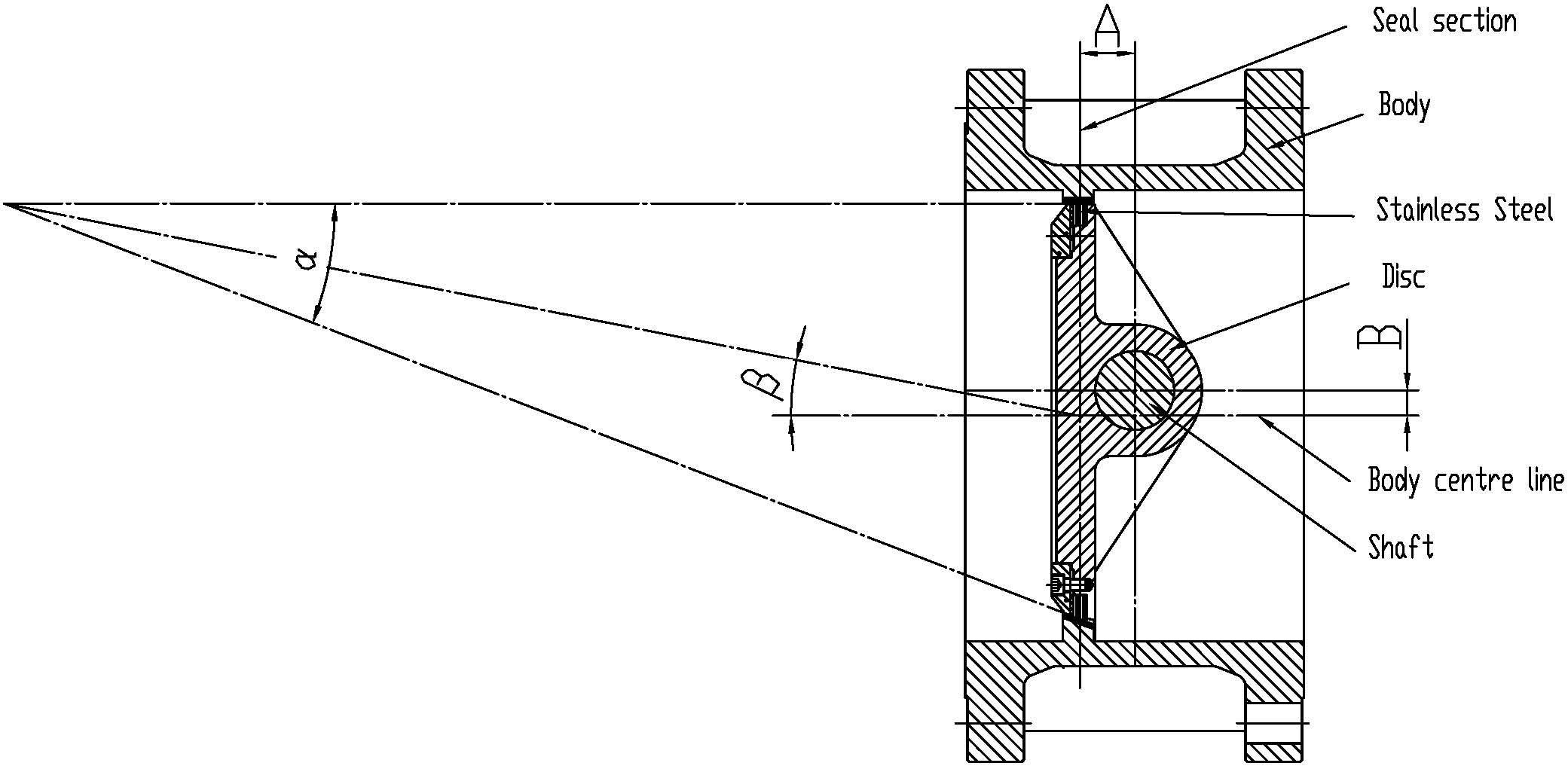

Umfanekiso wesi-2 Ivalve yebhabhathane yokutywina yentsimbi ephindwe kathathu yimveliso eqhelekileyo ye-BVMC, njengoko kubonisiwe kumzobo wesi-2.

(a) Iimpawu zoLwakhiwo: Umbindi ojikelezayo wepleyiti yebhabhathane (okt iziko levalve) kukwenza icala elingu-A ngomphezulu wokutywina wepleyiti yebhabhathane, kunye nokuthambekela ku-B ngomgca osembindini womzimba wevalvu.Kwaye i-engile βbe idalwe phakathi komgca osembindini wobuso betywina kunye nomzimba wesihlalo (okt, umgca weaxial womzimba)

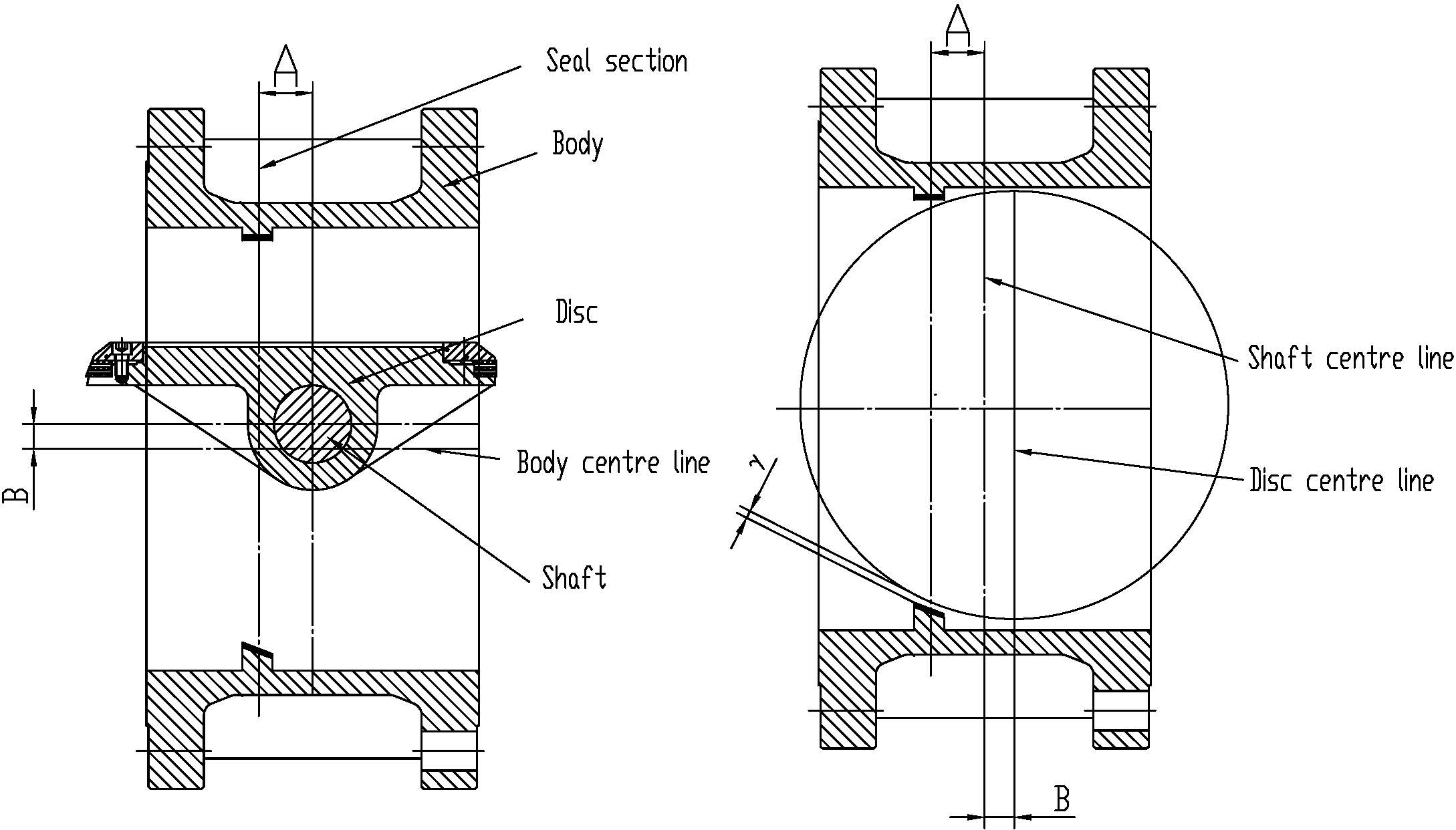

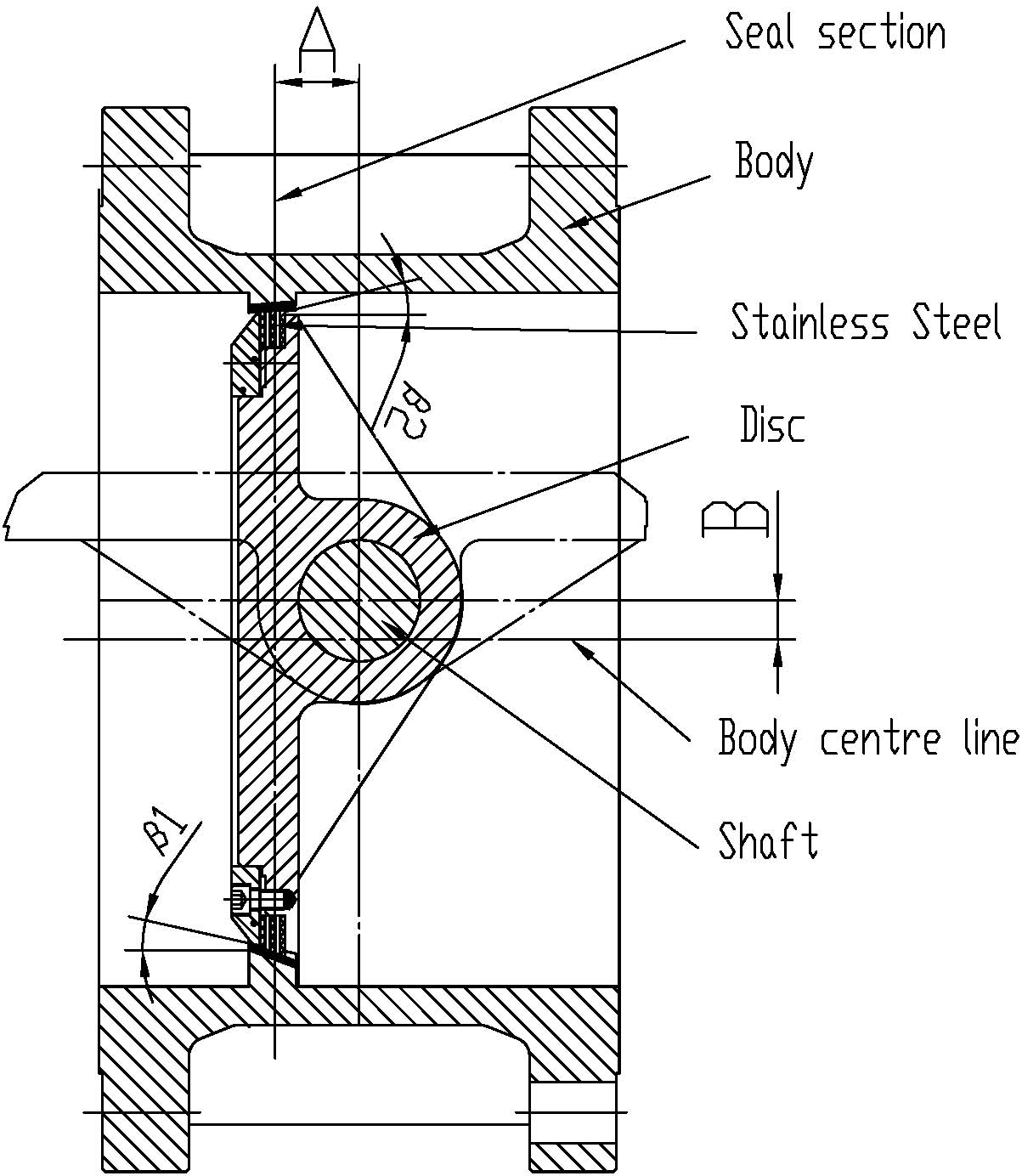

(b) Umgaqo-siseko wokutywinwa: Ngokusekelwe kwi-valve ye-butterfly ephindwe kabini, i-valve ye-butterfly eccentric ephindwe kathathu iphuhlise i-Angleβ phakathi kweendawo eziphambili zesihlalo kunye nomzimba.Impembelelo yecala njengoko kubonisiwe kumfanekiso 3 wecandelo elinqamlezayo.Xa ivalve yebhabhathane etywina kathathu ikwindawo evuleke ngokupheleleyo, umphezulu wokutywina webhabhathane uya kwahlulwa ngokupheleleyo kumphezulu wokutywina wesihlalo sevalve.Kwaye kuya kwenza ucoceko γphakathi kwepleyiti yebhabhathane etywina ubuso kunye nomphezulu wokutywina womzimba ngokufanayo nevalve yebhabhathane ephindwe kabini.Njengoko kubonisiwe kumfanekiso we-4, ngenxa yokubunjwa kwe-angle ye-β, i-anglesβ1 kunye ne-β2 iya kwenza phakathi komgca we-tangent we-disc yokujikeleza kunye ne-valve seat yokutywinwa kwendawo.Xa uvula kwaye uvala i-disc, i-butterfly plate yokutywina ipleyiti iya kuhlukana ngokuthe ngcembe kwaye idibanise, kwaye emva koko ikhuphe ngokupheleleyo ukunxiba kunye nokukhwabanisa.Xa kuvuleka ivalve, indawo yokutywina idiskhi iya kwahlula ngoko nangoko kwisitulo sevalve.Kwaye kuphela ngexesha elivaliweyo ngokupheleleyo, i-disc iya kuhlanganisana kwisihlalo.Njengoko kubonisiwe kumzobo4, ngenxa yokwenziwa kwe-engile β1 kunye ne-β2, xa ivalve yebhabhathane ivaliwe, uxinzelelo lwetywina luveliswa nge-valve shaft drive torque generation hayi ukuguquguquka kwesitulo sevalve yebhabhathane.Ayinakuphelisa kuphela ukubakho kokunciphisa isiphumo sokutywinwa kunye nokusilela okubangelwa kukwaluphala kwezinto zokuhlala, ukuhamba okubandayo, izinto ezingasebenziyo, kwaye zinokuhlengahlengiswa ngokukhululekileyo nge-torque ye-drive, ukuze ukusebenza kokutywinwa kwevalve yebhabhathane kathathu kunye nobomi bokusebenza kuya kuba kakhulu. iphuculwe.

Umzobo 2 I-Triple eccentric ephindwe kabini yentsimbi etywiniweyo ivelufa yebhabhathane

Umzobo 3 Idayagram ye-eccentric ephindwe kabini yentsimbi etywina ibhabhathane ivelufa kwindawo evulekileyo

Umzobo 4 Idayagram ye-eccentric ephindwe kabini yentsimbi yokutywina ivalve yebhabhathane kwindawo ekufutshane

6.1 Ufakelo

6.1.1 Ukuqwalasela ngononophelo imixholo yesivalo segama levalve phambi kokufaka, qinisekisa ukuba uhlobo, ubungakanani, imathiriyeli yesitulo kunye nobushushu bevalvu ziya kuhambelana nenkonzo yombhobho.

6.1.2 Ukutshekisha kukhethwa zonke iibholithi eziqhagamsheleneyo phambi kofakelo, uqinisekise ukuba ziyaqina ngokulinganayo.Kwaye ukujonga ukuba ngaba ukunyanzeliswa kunye nokutywinwa kokupakisha.

6.1.3 Ivalve yokutshekisha eneempawu zokuqukuqela, ezifana nokubonisa icala oya ngakulo,

Kwaye ukufaka i-valve kufuneka kuhambelane nemimiselo yokuhamba.

6.1.4 Umbhobho kufuneka ucocwe kwaye ususwe ii-oyile zawo, i-welding slag kunye nobunye ukungcola phambi kokufakwa.

6.1.5 Ivalve kufuneka ikhutshwe ngobunono, ithintele ukujulwa kwayo kunye nokuwisa.

6.1.6 Kufuneka sisuse isigqubuthelo sothuli ekupheleni kwevalve xa sifaka ivalve.

6.1.7 Xa ufaka i-valve, ubukhulu be-gasket ye-flange bungaphezulu kwe-2 mm kunye nokuqina konxweme kungaphezulu kwe-70 PTFE okanye i-gasket ejikelezayo, i-flange yeebholiti ezidibanisayo kufuneka ziqiniswe nge-diagonally.

6.1.8 Ukukhululeka kokupakisha kunokubangelwa kukutshintsha kokungcangcazela kunye nobushushu kuthutho, kunye nokuqiniswa kwamandongomane edlala lokupakisha ukuba kukho ukuvuza ekutywinweni kwesikhondo emva kofakelo.

6.1.9 Ngaphambi kokufaka ivalve, indawo ye-actuator ye-pneumatic kufuneka imiselwe, ukuze kuqhutywe umsebenzi owenziweyo kunye nokugcinwa phantsi kokungalindelekanga.Kwaye i-activator kufuneka ihlolwe kwaye ivavanywe phambi kokuba ifakwe kwimveliso.

6.1.10 Uhlolo olungenayo kufuneka lube ngokwemigangatho efanelekileyo.Ukuba indlela ayichanekanga okanye yenziwe ngumntu, iNkampani ye-BVMC ayizukuthatha naluphi na uxanduva.

6.2 Ukugcinwa kunye noLondolozo

6.2.1 Iziphelo kufuneka zogqunywe ngesigqubuthelo sothuli kwigumbi elomileyo nelingena umoya, ukuqinisekisa ukusulungeka komngxuma wesivalo.

6.2.2 Xa i-valve yokugcina ixesha elide iphinda isetyenziswe kwakhona, ukupakisha kufuneka kuhlolwe ukuba akuvumelekile kwaye kuzalise ioli ye-lubricant kwiindawo ezijikelezayo.

6.2.3 Iivalvu mazisetyenziswe kwaye zigcinwe ngexesha lewaranti (ngokwemvumelwano), kubandakanywa ukutshintshwa kwegasket, ukupakisha njl.

6.2.4 Iimeko zokusebenza zesivalo kufuneka zihlale zicocekile, kuba zinako ukwandisa ubomi bayo benkonzo.

6.2.5 Iivalvu kufuneka zihlole kwaye zigcinwe rhoqo xa zisebenza ukuze zikhuseleke ekutyeni kwaye ziqinisekise ukuba isixhobo sikwimeko entle.

Ukuba i-medium ngamanzi okanye i-oyile, kucetyiswa ukuba izivalo kufuneka zihlolwe kwaye zigcinwe rhoqo kwiinyanga ezintathu.Kwaye ukuba i-medium is corrosive, kucetyiswa ukuba zonke iivalve okanye inxalenye yevalve kufuneka ihlolwe kwaye igcinwe inyanga nenyanga.

6.2.6 Ivalve yoxinzelelo lokucoca umoya kufuneka ikhuphe rhoqo, ikhuphe ungcoliseko, ithathe indawo yesihluzo.Ukugcina umoya ucocekile kwaye womile ukuphepha ungcoliseko lwamalungu e-pneumatic, imbangela yokungaphumeleli.(Ukubona "umyalelo wokusebenza kwe-pneumatic actuator")

6.2.7 Umbhobho, amalungu e-pneumatic kunye nemibhobho kufuneka zitshekishwe ngononophelo kwaye rhoqo ukuthintela ukuvuza kwegesi (Ukubona "umyalelo wokusebenza kwe-pneumatic actuator")

6.2.8 Xa kulungiswa iivalvu ziya kugungxula amalungu kwakhona, ukususa umzimba wangaphandle, amabala kunye nebala elinomhlwa.Ukutshintsha i-gaskets eyonakalisiweyo kunye nokupakisha, indawo yokutywina kufuneka ilungiswe.Uvavanyo lwe-hydraulic kufuneka luqhutywe kwakhona emva kokulungiswa, abaqeqeshiweyo banokusebenzisa.

6.2.9 Inxalenye yomsebenzi wevalvu (efana nesiqu kunye ne-packing seal) kufuneka igcinwe icocekile kwaye yosule uthuli ukuze ikhuseleke ekugqabhukeni nasekudlekeni.

6.2.10 Ukuba kukho ukuvuza kwipakethe kwaye i-packing gland nuts kufuneka iqiniswe ngokuthe ngqo okanye itshintshe ukupakisha ngokwemeko.Kodwa akuvumelekanga ukutshintsha ukupakisha ngoxinzelelo.

6.2.11 Ukuba ukuvuza kwevalve akusonjululwanga kwi-intanethi okanye kwezinye iingxaki zokusebenza, xa kususwa isivalo kufuneka kube ngokwala manyathelo alandelayo:

a.Nika ingqalelo kukhuseleko: ukhuseleko lwakho, ukususa ivalve kumbhobho kuqala kufuneka uqonde ukuba yintoni na into ephakathi kumbhobho.Kufuneka unxibe izixhobo zokukhusela abasebenzi ukukhusela okuphakathi ngaphakathi komonakalo wombhobho.Ngaxeshanye ukuqinisekisa ukuba umbhobho woxinzelelo oluphakathi sele.Ivalve kufuneka ivalwe ngokupheleleyo phambi kokuba isuse ivalve.

b.Ukususa isixhobo somoya (kubandakanya umkhono wokudibanisa, Ukubona "umyalelo wokusebenza kwe-pneumatic actuator") kufuneka uqaphele ukusebenza ukuze ugweme umonakalo ovela kwisiqu kunye nesixhobo somoya;

c.Iringi yokutywina yediski kunye nesitulo kufuneka ikhangelwe ukuba ayinawo na umkrwelo xa ivalve yebhabhathane ivuliwe.Ukuba kukho umkrwelo omncinci wesitulo, unokusebenzisa ilaphu le-emery okanye i-oyile kwindawo yokutywina ukuze iguqulwe.Ukuba umkrwelo omncinci onzulu ubonakala, amanyathelo afanelekileyo kufuneka athathwe ukulungisa, ivalve yebhabhathane ingasebenzisa emva kovavanyo olufanelekileyo.

d.Ukuba isiqu esipakishweyo siyavuza, idlala lokupakisha kufuneka lisuse, kwaye kujongwe isiqu kunye nokupakishwa komphezulu, ukuba isiqu sinomkrwelo, ivalve kufuneka idibane emva kokulungiswa.ukuba ukupakisha konakalisiwe, ukupakisha makutshintshwe.

e.Ukuba i-cylinder ineengxaki, iya kukhangela amacandelo e-pneumatic, iqinisekise ukuba ukuhamba kwendlela yegesi kunye noxinzelelo lomoya, ivalve yokubuyisela umbane ye-electromagnetic iyinto eqhelekileyo.Ukubona "umyalelo wokusebenza kwe-pneumatic actuator")

f.Xa igesi ifakwe kwisixhobo somoya, iqinisekisa ukuba akukho cylinder ngaphakathi nangaphandle akukho kuvuza.Ukuba isixhobo somoya sitywinwe sithe sonakalisiwe singakhokelela ekucuthekeni koxinzelelo lwetorque, ukuze ingahlangani nevalve yebhabhathane yokuvula nokuvala, iya kuhoya uhlolo oluthe gqolo kunye nokutshintshwa kwamalungu.

Ivalve yebhabhathane yepneumatic ezinye iindawo azilungisi.Ukuba umonakalo unzima, kufuneka uqhagamshelane nomzi-mveliso okanye uthumele ukugcinwa kwefektri.

6.2.12 Uvavanyo

I-valve iya kuba uvavanyo loxinzelelo emva kokuba i-valve ilungise uvavanyo ngokuhambelana nemigangatho efanelekileyo.

6.3 Umyalelo wokusebenza

6.3.1 Ivalve esebenza ngepneumatic enesixhobo somqhubi wesilinda iya kwenziwa ukuba idiski ijikeleziswe ngama-90° ukuvula okanye ukuvala ivalve.

6.3.2 Izalathisi-ndlela ezivulelekileyo zevalve yebhabhathane esebenza emoyeni ziya kuphawulwa ngesalathisi sendawo kwisixhobo somoya.

6.3.3 Ivalve yebhabhathane ene-truncation kunye nentshukumo yohlengahlengiso ingasetyenziswa njengokutshintsha kolwelo kunye nolawulo lokuqukuqela.Ngokuqhelekileyo akuvunyelwanga ngaphaya koxinzelelo - imeko yomda weqondo lobushushu okanye ukutshintshwa rhoqo koxinzelelo kunye neemeko zobushushu

6.3.4 Ivalve yebhabhathane inamandla okuxhathisa umahluko woxinzelelo oluphezulu, musa ukuvumela ivalve yebhabhathane ivuleke phantsi koxinzelelo oluphezulu nokuba kuluhlu loxinzelelo oluphezulu luyaqhubeka ukujikeleza.Kungenjalo kunokubangela umonakalo, okanye ingozi enkulu yokhuseleko kunye nelahleko yepropathi.

6.3.5 Iivalve ze-pneumatic zisebenzisa rhoqo, kwaye ukusebenza kwentshukumo kunye neemeko zokuthambisa kufuneka zihlolwe rhoqo.

6.3.6 Isixhobo sepneumatic ngasemva ukuze ivalve yebhabhathane ivaleke, iphinde iphindene newotshi ukuze ivalve yebhabhathane ivuleke.

6.3.7 Ukusebenzisa ivalve yebhabhathane yepneumatic kufuneka ithathele ingqalelo umoya ucocekile, uxinzelelo lonikezelo lomoya yi-0.4 ~ 0.7 Mpa.Ukugcina iipaseji zomoya zivulekile, akuvumelekanga ukuvala ukungena komoya kunye nokuhamba komoya.Ngaphambi kokuba isebenze, kufuneka ingene kumoya ocinezelweyo ukuze ijonge ukuba intshukumo yevalve yebhabhathane yepneumatic iqhelekile.nikela ingqalelo kwivalve yebhabhathane evulekileyo okanye evaliweyo, nokuba idiski ikwindawo evulekileyo okanye evaliweyo.Ukunyamekela indawo yevalve kunye nesikhundla se-cylinder sihambelana.

6.3.8 Ubume be-pneumatic actuators crank arm yintloko exande, esetyenziselwa isixhobo semanuwali.Xa kwenzeka ingozi, inokususa umbhobho wokuhambisa umoya ngokuthe ngqo kunye ne-wrench ukuba umsebenzi owenziwe ngesandla unokufezekiswa.

7. Iimpazamo, izizathu kunye nesisombululo (Jonga iTab 1)

Ithebhu 1 Iingxaki ezinokwenzeka, izizathu kunye nesisombululo

| Iimpazamo | Unobangela wokusilela | Isisombululo |

| Ivalve eshukumayo inzima, ayiguquguquki | 1. Iintsilelo zeActuator2.Vula itorque inkulu kakhulu3.Uxinzelelo lomoya luphantsi kakhulu 4.Ukuvuza kwesilinda | 1. Lungisa kwaye ujonge isekethe yombane kunye negesi yegesi kwisixhobo somoya2.Ukunciphisa ukulayishwa komsebenzi kunye nokukhetha izixhobo ze-pneumatic ngokuchanekileyo3.Ukwandisa uxinzelelo lomoya 4. Khangela iimeko zokutywinwa kwi-cylinder okanye umthombo wokudibanisa |

| I-Stem Packing Leakage | 1. Ukupakisha iibholithi zedlala kukhululekile2.Ukupakishwa komonakalo okanye isiqu | 1. Qinisa iibholithi zedlala2.Faka indawo yokupakisha okanye isiqu |

| Ukuvuza | 1.Indawo yokuvala isekela lokutywina ayichanekanga | 1. Ukulungelelanisa i-activator ukwenza indawo yokuvala isekela lokutywina ichanekile |

| 2. Ukuvala akufikeleli kwindawo echongiweyo | 1.Ukukhangela isalathiso se-open-close sisendaweni2.Ukulungelelanisa ngokuhambelana neenkcukacha ze-actuator, ukwenzela ukuba ulwalathiso luhambelane nemeko ye-open3 yangempela.Ukujonga izinto zokubamba kukwipayipi | |

| 3. Iinxalenye zomonakalo wevalvu①Umonakalo wesihlalo②Umonakalo wediski | 1. Buyisela isihlalo2.Tshintsha idiski | |

| Ukuphelelwa kwe actuator | 1.Umonakalo ongundoqo kunye ne-drop2.I-pin yokumisa inqunyulwe | 1. Faka indawo yesitshixo phakathi kwesiqu kunye ne-actuator2.Buyisela iphini lokumisa |

| Ukusilela kwesixhobo somoya | Ukubona "iinkcukacha zesixhobo se-valve pneumatic" | |

Qaphela: Abasebenzi besondlo baya kuba nolwazi olufanelekileyo kunye namava.

Ixesha lokuposa: May-19-2022