1. Umda

Uluhlu lwe-DN lubandakanya i-DN15mm ~ 600mm (1/2"~24") kunye noluhlu lwe-PN ukusuka kwi-PN1.6MPa ~ 20MPa (ANSI CLASS150 ~ 1500) intambo, i-flanged, i-BW kunye ne-SW swing kunye nokuphakamisa i-valve yokujonga.

2.Ukusetyenziswa:

2.1 Le valve kukuthintela ukuhamba okuphakathi ngasemva kwisixokelelwano semibhobho.

2.2 Imathiriyeli yevalvu ikhethwa ngokuphakathi.

2.2.1Ivalve yeWCB ilungele amanzi, umphunga kunye neoyile medium njl.

2.2.2Ivalve ye-SS ifanelekile kwi-corrosion medium.

2.3 Ubushushu:

2.3.1I-WCB eqhelekileyo ilungele ubushushu -29℃ ~+425℃

2.3.2Ivalve yengxubevange ilungele ubushushu≤550℃

Ivalve ye-2.3.3SS ilungele ubushushu-196℃ ~+200℃

3. Isakhiwo kunye neempawu zokusebenza

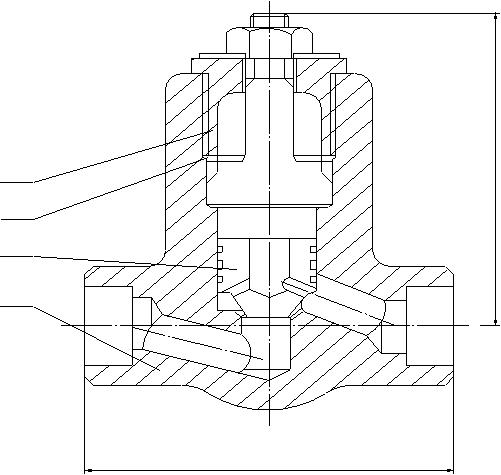

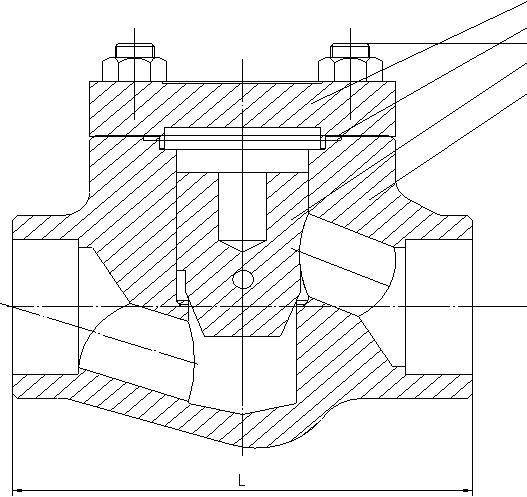

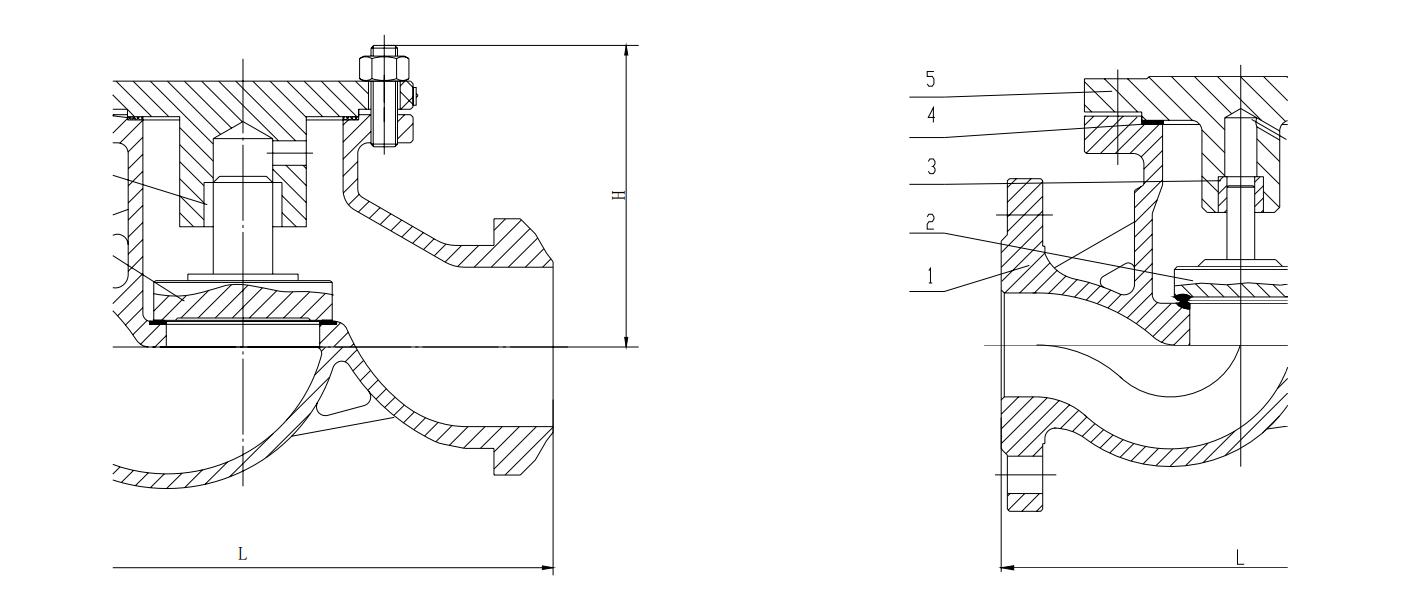

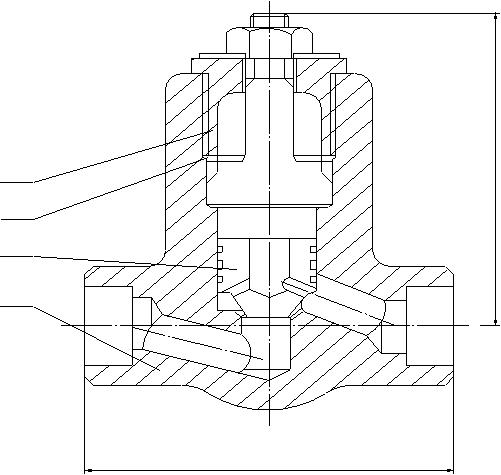

3.1 Ubume obusisiseko bunje ngezantsi:

3.2 I-PTFE kunye negraphite eguquguqukayo yamkelwa kwi-gasket eyonakalisayo ukuqinisekisa ukusebenza kokutywinwa.

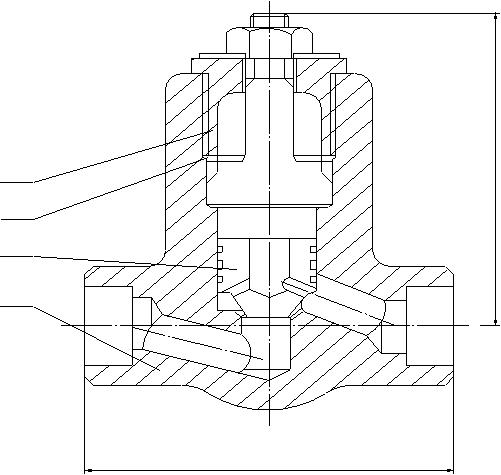

(A) I-Welding eyakhiwe ngoxinzelelo oluphezulu oluzitywinayo oluphakamisa ivalve yokukhangela

(B) Ukuwelda ivalve yetshekhi yokunyusela ngomkhandi

1.umzimba 2. idiskhi 3. gasket 4. ibhonethi

(C) I-BW yokuPhakamisa iValve yokuHlola

(D) I-valve yokuHlola eneFlanged

1.Umzimba 2. I-Disc 3. I-Shaft 4. I-Gasket 5. Ibhonethi

(E)BW Swing Check Valve

(F) Ukujongwa kwe-Flanged Swing

1.Umzimba 2. Isihlalo 3. Disc 4. Rocker Arm 5. Pin Shaft 6. Yoke 7. Gasket 8. Bonnet

3.3 Izixhobo ezingundoqo

| Igama | Izinto eziphathekayo | Igama | Izinto eziphathekayo |

| Umzimba | Intsimbi yeCarbon, iSS, iAlloy Steel | I-Pin Shaft | SS, Cr13 |

| Isitulo seTywina | I-Surfacing13Cr, STL, Rubber | Idyokhwe | Intsimbi yeCarbon, iSS, iAlloy Steel |

| Icwecwe | Intsimbi yeCarbon, iSS, iAlloy Steel | Gasket | PTFE, Flexible Graphite |

| Ingalo yeRocker | Intsimbi yeCarbon, iSS, iAlloy Steel | Ibhonethi | Intsimbi yeCarbon, iSS, iAlloy Steel |

3.4 Itshathi yokuSebenza

| Ukukala | Uvavanyo lwamandla (MPa) | Uvavanyo lwetywina (MPa) | Uvavanyo lwetywina lomoya (MPa) |

| Iklasi150 | 3.0 | 2.2 | 0.4~0.7 |

| Iklasi300 | 7.7 | 5.7 | 0.4~0.7 |

| Iklasi600 | 15.3 | 11.3 | 0.4~0.7 |

| Iklasi900 | 23.0 | 17.0 | 0.4~0.7 |

| Iklasi1500 | 38.4 | 28.2 | 0.4~0.7 |

| Ukukala | Uvavanyo lwamandla (MPa) | Uvavanyo lwetywina (MPa) | Uvavanyo lwetywina lomoya (MPa) |

| 16 | 2.4 | 1.76 | 0.4~0.7 |

| 25 | 3.75 | 2.75 | 0.4~0.7 |

| 40 | 6.0 | 4.4 | 0.4~0.7 |

| 64 | 9.6 | 7.04 | 0.4~0.7 |

| 100 | 15.0 | 11.0 | 0.4~0.7 |

| 160 | 24.0 | 17.6 | 0.4~0.7 |

| 200 | 30.0 | 22.0 | 0.4~0.7 |

4. Ithiyori yomsebenzi

Ivalve yokujonga ivula ngokuzenzekelayo kwaye ivale idiski ukuthintela ukuhamba okuphakathi ngasemva ngokuhamba okuphakathi.

5. Imigangatho yevalvu esebenzayo kodwa ayiphelelanga apha:

(1) API 6D-2002 (2) ASME B16.5-2003

(3) ASME B16.10-2000 (4) API 598-2004

(5) GB/T 12235-1989 (6) GB/T 12236-1989

(7) GB/T 9113.1-2000 (8) GB/T 12221-2005 (9) GB/T 13927-1992

6. Ukugcinwa kunye noLondolozo kunye noFakelo kunye nokusebenza

6.1 Ivalve kufuneka igcinwe kwigumbi elomileyo nelingena umoya.

6.2 Iivalvu eziphantsi kogcino lwexesha elide kufuneka zihlolwe kwaye zicocwe rhoqo, ingakumbi indawo yokuhlala ukuze kuthintelwe ukonakaliswa kwayo, kwaye indawo yokuhlala kufuneka igqunywe nge-rust inhibiting oil.

6.3 Ukumakishwa kweValve makutshekishwe ukuhambelana nokusetyenziswa kwayo.

6.4 Umgodi wevalvu kunye nomphezulu wokutywina kufuneka uhlolwe phambi kofakelo kwaye kususwe ukungcola ukuba kukho.

6.5Icala lotolo kufuneka lifane nela ngakulo.

6.6 Ukuphakamisa ivalve yokujonga idiski emileyo kufuneka ifakwe ngokuthe nkqo kumbhobho.Ivalve yokujonga idiski ethe tyaba kufuneka ifakwe ngokuthe tye kumbhobho.

6.7 Ukungcangcazela kufuneka kujongwe kwaye utshintsho lwemibhobho yoxinzelelo oluphakathi kufuneka luqatshelwe ukuthintela ukusebenza kwamanzi.

7.Iingxaki ezinokwenzeka, izizathu kunye nomlinganiselo wokulungisa

| Iingxaki ezinokwenzeka | Oonobangela | Umlinganiselo woLungiso |

| Idiski ayikwazi ukuvula okanye ukuvala |

| |

| Ukuvuza |

| |

| Ingxolo kunye neVibration |

|

8. Iwaranti

Emva kokuba ivalve isetyenziswe, ixesha lewaranti yevalve ziinyanga ezili-12, kodwa alidluli kwiinyanga ezili-18 emva komhla wokuhanjiswa.Ngexesha lewaranti, umenzi uya kubonelela ngenkonzo yokulungisa okanye iinxalenye ezisecaleni ngaphandle kwentlawulo ngenxa yomonakalo ngenxa yezinto, umsebenzi okanye umonakalo ngaphandle kokuba umsebenzi uchanekile.

Ixesha lokuposa: May-19-2022